BLDC Motor Drive Explained: What Really Makes an Inverter Washer Feel “Quiet”?

A “quiet” washer is not just a marketing word. When you are sourcing an inverter washing machine motor for export, quiet is a real buying reason, a real review trigger, and sometimes a real return reason. The sound you get in the customer’s home comes from a chain: the motor, the BLDC motor inverter, the control code, the drum load, and how the vibration travels into the cabinet.

If you want a practical reference point for building that chain well, start with a supplier that already lives inside high-volume home appliance motor work. Huzhou Nanyang Electric-Motor Co., Ltd. is built around motor R&D and manufacturing, with large-scale production planning, independent testing capability, and a dedicated R&D structure that supports platform matching in real projects. When you want to spec a quiet inverter washing machine, that mix of engineering and factory discipline matters more than a single brochure number.

What Does “Quiet” Really Mean in an Inverter Washing Machine?

Quiet is a feeling first, then a measurement. Customers rarely describe a washer as “72 dB.” They say “it whines,” “it shakes,” “it sounds smooth,” or “it feels cheap.” A good BLDC motor drive can change that experience, but only if you know what kind of noise you are chasing and where it is born.

Sound Profile vs Decibel Numbers

A quiet inverter washing machine usually means fewer sharp tones. High-pitch PWM whine, mid-band buzzing, and low-frequency rumble hit people harder than steady water noise. That is why inverter washer noise reduction is often about sound shape, not only sound level. When your washing machine inverter motor holds speed smoothly, the “nervous” sound goes away and the washer feels calmer.

Noise Sources Buyers Actually Hear

In real homes, the common culprits stack up: motor electromagnetic tones, bearing and belt noise, water slosh, and cabinet resonance. One small problem becomes loud when it matches the cabinet’s natural frequency. That is why washing machine vibration and noise causes often look like a system issue, not a single part issue.

Where the Motor and Drive Make the Biggest Difference

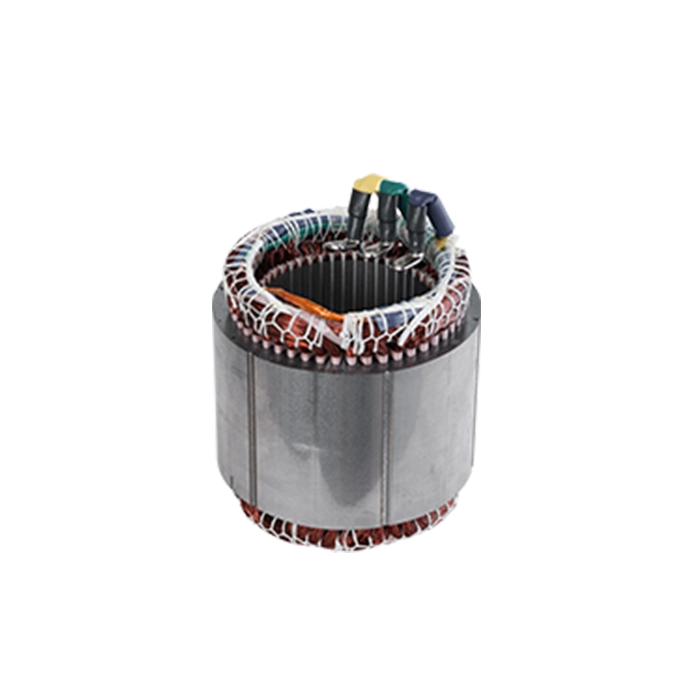

The motor and drive dominate the “machine-made” noise. A stable BLDC motor inverter and BLDC motor control loop can cut speed ripple, reduce torque ripple, and keep the drum from doing tiny accelerations that your ear hears as roughness. In the knowledge base, Nanyang highlights low-noise design choices like an optimized stator structure and a balanced rotor, built around the quiet home appliance trend.

How Does a BLDC Motor Drive Work in a Washing Machine?

If you need to explain how BLDC motor drive works in washing machine platforms to a buyer or a product manager, keep it simple: power goes in, switching happens, torque comes out, and the controller keeps correcting. The “quiet” part is basically how gently that correction happens.

BLDC Motor Drive Energy Flow in One Loop

AC mains becomes DC on the bus, then the inverter switches that DC into three-phase current. That current creates a rotating field in the stator and the rotor follows. The control loop reads speed or estimates it, then adjusts phase current. This is the BLDC motor inverter drive principle in plain terms. When the loop is stable, inverter washer smooth operation is not a mystery. It is feedback that does not overreact.

BLDC Motor Inverter Hardware Blocks

Your BLDC motor inverter normally includes the rectifier, DC link, switching stage, gate drive, current sensing, and protection. Hardware quality shows up as fewer weird noises under load changes, fewer nuisance trips, and less heat drift. In the knowledge base, Nanyang describes multi-step end-to-end testing and independent electrical testing capability with more than 30 steps, which helps control defect rate in mass production.

Control Stack That Shapes Feel and Noise

BLDC motor control is not one thing. It is a stack: current loop, speed loop, commutation logic, startup strategy, and sometimes load detection. Inverter motor speed control washing machine performance depends on how those layers are tuned. If you tune for “fast response only,” you often get more audible correction. If you tune for smoothness, you usually get less harsh sound.

Which Inverter Control Choices Cut Inverter Washer Noise the Most?

There is a reason buyers keep searching for inverter motor noise control and motor drive algorithm noise reduction. The most annoying washer sounds are often created by control choices that look harmless on paper.

Vector Control vs Trapezoidal Control Tradeoffs

Vector control vs trapezoidal control BLDC is not just an academic argument. Trapezoidal control can be cost-friendly and simple, but it can raise torque ripple, especially at low speed. That ripple can become a pulsing sound in the tub. Vector control can improve smoothness, but it asks for better sensing, better models, and better tuning work.

PWM Strategy and Switching Frequency Effects

PWM control in inverter washing machine designs is a common source of high-frequency whine. Motor drive frequency and noise are connected in a very direct way: if the switching frequency sits in or near the audible band, you can hear it. If it is pushed higher, you may hear less, but you can increase switching loss and heat.

Torque Ripple Reduction as a Noise Lever

BLDC motor torque ripple reduction is one of the fastest ways to make a washer feel premium. Ripple becomes vibration, then the cabinet turns it into sound. Current shaping, commutation overlap, better rotor balance, and a stable current loop can all help.

How Do You Choose an Inverter Washing Machine Motor Supplier for Low-Noise Platforms?

Start with the right motor family for your platform. For inverter washer designs that target smooth speed control and low audible noise, a dedicated BLDC motor washing machine solution is the normal path. Nanyang’s home appliance portfolio covers multiple motor categories, and its drum BLDC motor line is positioned as a high-volume category in its product notes. To see the product entry directly, use this page: BLDC Motor.

Engineering Depth and Noise Validation

Noise performance is partly design, partly factory discipline. Nanyang’s scale includes multiple production bases and large planned output, plus dedicated R&D departments and a patent portfolioincluding over 100 patents across invention, utility, and design categories. It also mentions independent electrical testing capability and multi-step end-to-end testing. That is the kind of base you want when your customer cares about inverter washer noise reduction, not only motor efficiency.

Export Support and Response Speed

Export projects move fast until something fails in the field, then time becomes the whole game.Nanyang’s service support setup with rapid response and technical support timing, plus foreign trade coverage across many countries and year-on-year export growth.

When you are ready to talk specs, drawings, and validation plans, use the Contact Page and keep your request concrete: target spin profiles, load class, noise complaint type, and whether you need sensorless BLDC motor control washing machine behavior to be smooth at very low speed.

FAQ

Q1: Why inverter washers are quieter than conventional washers?

A: A well-tuned inverter drive holds motor speed more smoothly and avoids harsh torque steps.

Q2: Is BLDC motor washing machine quiet because of the motor, or the inverter control?

A: It is both. Motor design affects balance and electromagnetic smoothness, while the BLDC motor inverter and BLDC motor control loops shape how current becomes torque.

Q3: What is the biggest cause of washing machine motor vibration in export markets?

A: In many cases it is not one part. It is a combination of load imbalance, mounting stiffness, torque ripple, and cabinet resonance. Fixing vibration usually means controlling the vibration path, not only changing the motor.