What is the difference between inverter motor vs normal motor

In the fast-changing world of appliance and automotive technologies, picking between inverter motors and normal motors greatly affects efficiency, strength, and general output. If you are building a cutting-edge washing machine or choosing a budget-friendly option for basic uses, understanding the ways these two motor kinds vary can strongly influence your product’s market edge.

One firm that has steadily pushed forward in this area is Huzhou Nanyang Electric-Motor Co., Ltd.. With more than 30 years of knowledge in electric motor production, Nanyang provides a wide range of products including inverter motors, AC induction motors, and direct drive options suited for home appliances as well as new energy vehicles. Their focus on research and development, complete production integration, and smart manufacturing positions them as a reliable choice for superior motor requirements.

Key Structural Differences Between Inverter Motor and Normal Motor

Inverter Motor Uses Variable Frequency Drive for Speed Control

An inverter motor stands out because it includes a variable frequency drive (VFD). This setup lets it change its working frequency and voltage as needed. As a result, it offers exact control over motor speed and torque. Such technology supports gentle start and stop actions. These features lessen mechanical strain and boost energy savings. In devices like washing machines, this leads to improved care for fabrics and better use of water.

A clear example is the DDM Motor. It combines inverter control with a vertical direct-drive setup. This design reaches high motor efficiency over 80 percent. Therefore, it uses less power and runs with reduced noise.

Normal Motor Operates at Fixed Speed with Direct Power Input

On the other hand, a normal motor, often an AC induction type, works at a set speed based on the power supply’s frequency. It does not adapt well to changing needs. Moreover, it keeps running at full speed no matter the load. This approach makes it less effective in varying situations. It also speeds up damage to mechanical parts.

For example, the Wash Motor—a standard AC motor—delivers affordable results. However, it misses out on energy-saving features such as adjustable speed control or torque fine-tuning.

Construction Design Enhances Efficiency in Inverter Motors

Inverter motors usually have improved magnetic parts, stator windings, and rotor setups that cut down on losses and raise output. Reduced heat production not only raises energy savings but also extends working life.

The DD Motor serves as a strong case. Its horizontal direct-drive layout removes belt friction completely. This simple design betters torque delivery and lowers sound levels. Thus, it suits upscale washing machines well.

Performance Characteristics of Inverter Motor vs Normal Motor

Energy Efficiency Is Significantly Higher in Inverter Motors

A major benefit of inverter motors lies in their capacity to match power use to current load needs. This action cuts down on electricity waste. It also helps meet today’s energy-saving rules.

Nanyang’s inverter-based products, such as the DDM Motor, aid in creating eco-friendly appliances.

Noise and Vibration Are Lower in Inverter Motors

Thanks to even speeding up, slowing down, and no abrupt movements, inverter motors work quietly even with heavy loads. This quality matters a lot in home devices where comfort ranks high.

The DD Motor provides very quiet running with little shaking. As such, it improves the user’s overall experience in front-loading washing machines.

Torque Control Is More Precise in Inverter Technology

Inverter motors offer instant torque changes. This improves steadiness under different loads. It also cuts down on damage to inner parts. The outcome includes longer equipment durability and higher wash accuracy.

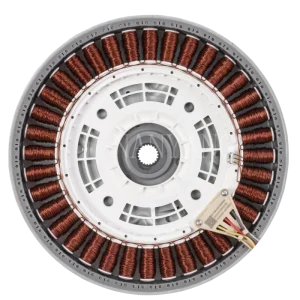

The detailed build of Nanyang’s Wash Motor shows these strengths. It supplies exact torque for drum turning in tough wash routines.

img.Wash Motor.webp

Application Scenarios and Use Cases for Each Motor Type

Inverter Motors Are Ideal for Variable Load Applications

In devices like washing machines that have various modes and load sizes, inverter motors allow smart dynamic management. This adaptability brings better results and smaller energy use in different situations.

Nanyang’s DDM Motor fits perfectly for smart appliance connections. It gives precise handling for tasks from light to heavy wash cycles.

Normal Motors Fit Simple, Cost-Conscious Applications

For uses that need steady performance without advanced control, normal motors give a wallet-friendly answer. Although their initial price is smaller, ongoing energy costs and upkeep fees tend to be larger.

The semi-automatic Wash Motor from Nanyang ensures dependable work for twin tub washing machines. It meets everyday home demands without fancy features.

Direct Drive Systems Benefit Most from Inverter Integration

Removing transmission belts boosts lasting power and savings. Direct drive setups powered by inverter motors make mechanical structures simpler. They also raise dependability.

The DD Series shows this method well. It offers an effective choice for front-loading washers with fewer upkeep needs.

Maintenance and Durability Considerations Between the Two Types

Inverter Motors Require Less Frequent Maintenance Intervals

Because of fewer moving elements and gentle start/stop functions, inverter motors build up less damage as time passes. This results in extended service periods and reduced total costs of ownership.

Nanyang’s DD Motor, made with in-house parts like enamelled wire and die-cast components, delivers strong reliability. It needs very little upkeep.

Normal Motors Experience Faster Component Degradation Over Time

Steady full-speed running hastens wear on brushes, bearings, and windings. This causes more regular fixes and possible stoppages. Such issues prove especially troublesome in business or heavy-use settings.

Thermal Management Is Superior in Inverter-Based Designs

Inverter-controlled work creates less extra heat. Advanced builds ensure stronger heat release during long runs. This lowers the chance of overheating.

Nanyang’s unique motor structure backs prolonged work cycles. It includes built-in heat safety steps.

Technological Advancements Driving Modern Motor Design

Integration with Smart Systems Enhances Inverter Functionality

Inverter motors link easily with IoT setups, remote checks, and AI methods. This creates fresh ways for forward-looking upkeep and flexible performance adjustments.

Nanyang’s R&D division works hard on improving smart solutions. These match worldwide trends in intelligent appliances.

Material Innovation Improves Performance Across Both Types

Employing materials with high permeability and rare-earth magnets raises power strength while shrinking size. These changes aid in reaching green goals without cutting back on output.

Sensor Feedback Loops Optimize Operational Precision

Closed-loop management through built-in sensors permits instant tweaks to speed and torque. This keeps steady work even in changing conditions.

The DDM motor’s included sensor setup aids exact automation in top-loading washers.

Environmental Impact Comparison Between the Two Technologies

Lower Carbon Footprint Achieved Through Energy Savings in Inverter Motors

By using just the right amount of electricity for each cycle, inverter motors sharply cut down on gases that warm the planet over their full life.

This fits nicely with worldwide efforts for sustainability in consumer electronics fields.

Noise Pollution Is Minimized by Smooth Operation of Inverter Motors

Silent running holds a key spot in city home areas where sound comfort counts. Direct drive inverter motors boost this greatly by cutting out belt sounds.

Lifecycle Sustainability Is Greater with Long-Life Components

Longer intervals between services mean fewer swaps and less waste from electronics as years go by.

Nanyang’s dedication to green production shows up in all parts of its inverter motor lineup.

Selecting the Right Washing Machine Motor Based on Application Needs

Evaluate Load Variability and Control Requirements Before Choosing a Motor Type

If your use calls for flexible work across different load amounts or wash styles, inverter-driven choices like the DDM or DD series make perfect picks.

Consider Energy Efficiency Goals When Selecting a Washing System Solution

Aiming for energy badges? The gains in efficiency from inverter motors make hitting those marks simpler than with usual induction builds.

Balance Cost, Performance, and Durability Based on Product Positioning Strategy

For models focused on value, standard AC choices like the Wash Motor give enough trustworthiness at smaller prices. For top-tier markets, focus on DDM or DD setups.

Explore Nanyang’s full product catalog to discover a custom fit that matches your use needs exactly.

FAQ

Q1: What’s the key reason inverter motors are more efficient than normal motors?

A: They adjust power consumption based on load conditions using variable frequency drives, reducing unnecessary energy waste.

Q2: Are DD or DDM motors better for high-end washing machines?

A: Yes, their direct drive structure eliminates belts, improving precision, reducing noise, and enhancing lifespan—ideal for premium models.

Q3: How does Nanyang ensure quality in its motor production?

A: Nanyang controls the entire production chain—from enamelled wire to final assembly—ensuring consistency and reduced defect rates.

Q4: Can Nanyang’s inverter motors integrate with smart appliances?

A: Yes, they support advanced protocols for IoT compatibility and adaptive algorithms for optimal performance management.

Q5: Where can I get technical support or request custom motor solutions?

A: You can reach out via the contact form on the Nanyang website or through their dedicated support channels.