The production chain is closely linked, and quality inspection is crucial.

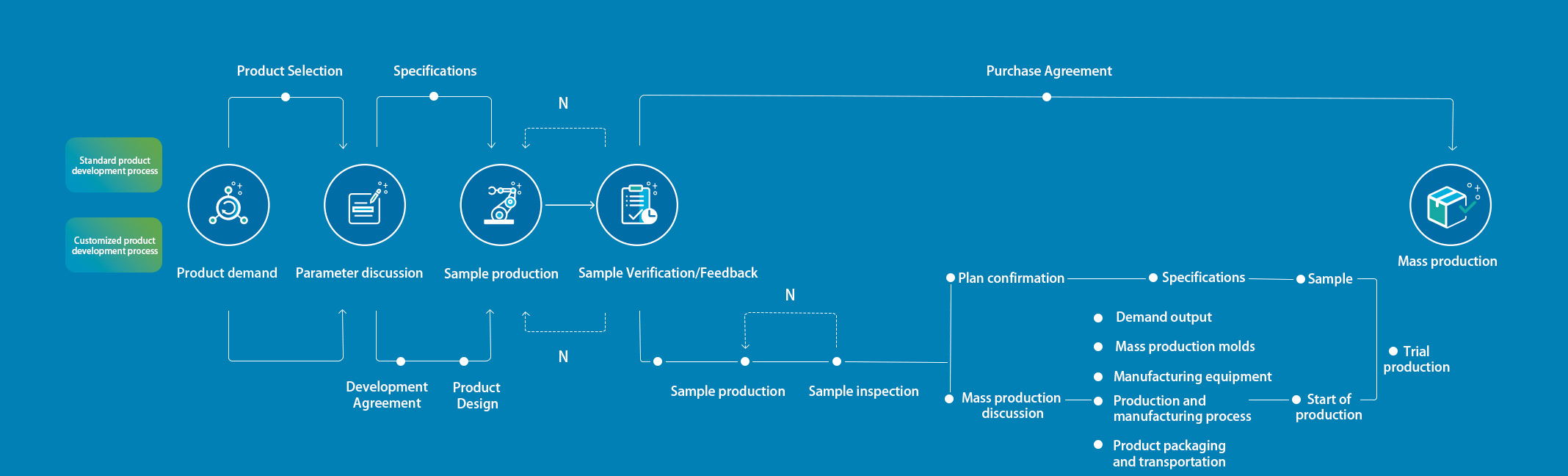

Both standard and customized products have clear and mature development processes.

One-stop Full Industrial Chain Manufacturing

Automated manufacturing production mode

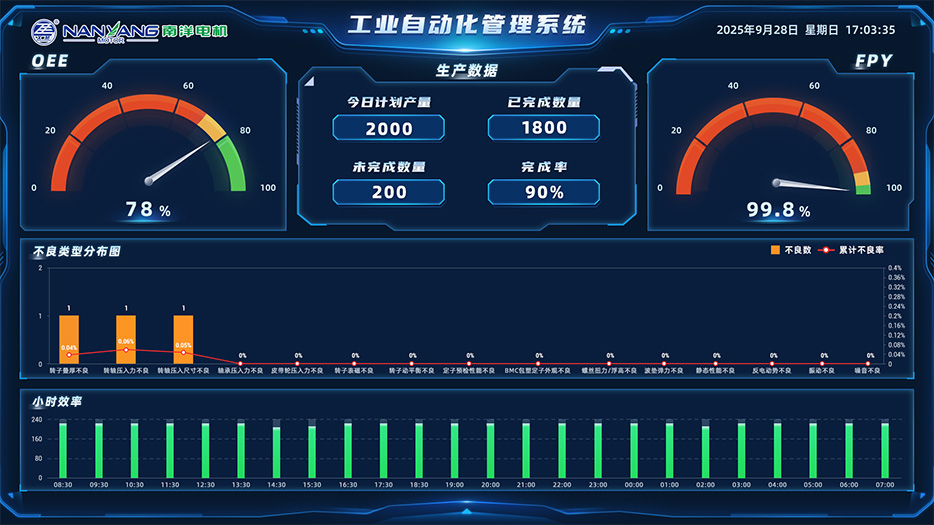

Nanyang possesses advanced flexible manufacturing and automated manufacturing capabilities, with a high degree of automation. The process automation rate reaching 82%. The CTQ process has achieved 100% automation; the average efficiency has increased by 21%.The quality control is highly efficient, and the key quality control points of CTF have achieved 100% automated inspection. Real-time online output is also provided. SPC control charts are generated.

All line has realized MES. Through the QR code on the surface of the stator core, the batch number of each purchased component and the detection data of each process can be traced. By introducing the MES management system and automated production line, the production flexibility has been effectively improved, the product quality has been ensured, and the cost has been reduced and the efficiency has been enhanced.

Intelligent logistics production mode

Raw material warehouse: AGV automatically picks up and places materials from the high-level shelves.

Production line: AGV automatically picks up goods from the ingredient area and delivers them to the designated points on the production line.

The implementation of AGVs is operated in conjunction with the warehouse’s WMES system. This fundamentally solves the problem of component first-in-first-out, and at the same time significantly improves the accuracy of component quality traceability.By implementing AGVs, it is estimated that will result in the elimination of logistics staff with a reduction rate of 75%.

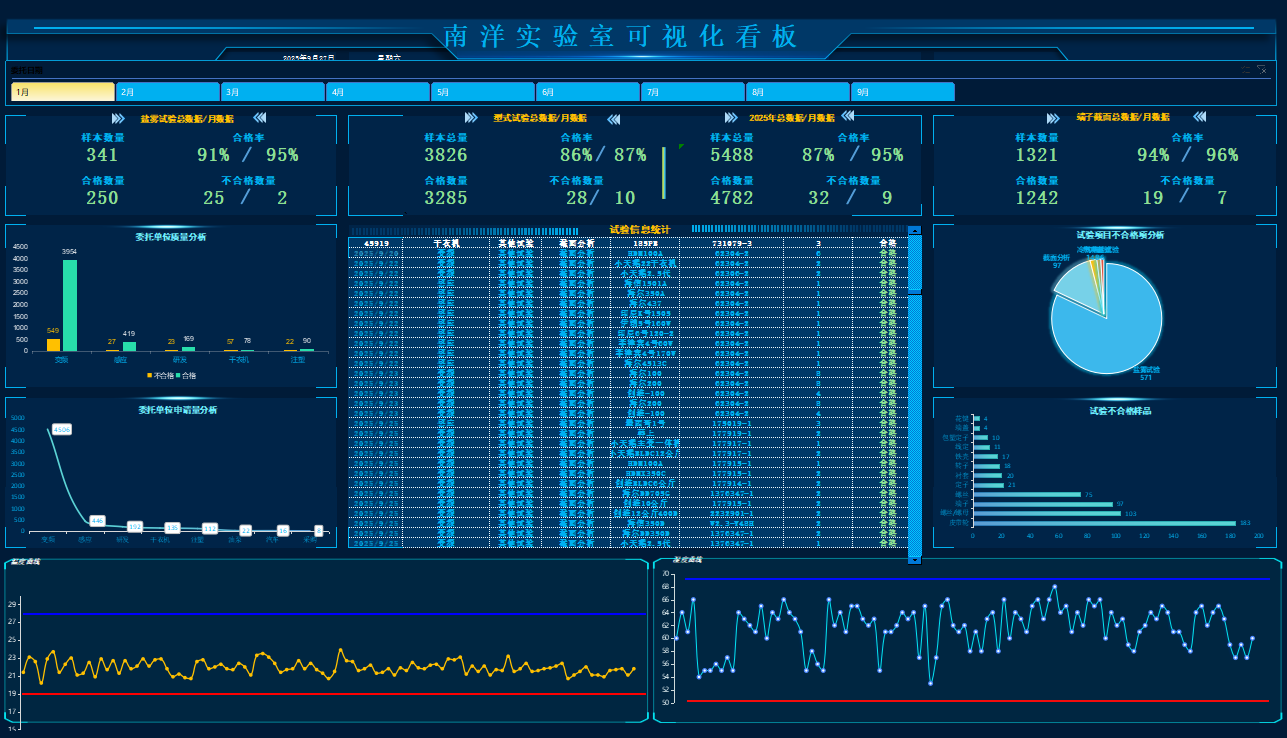

Informatization management production model

Precision management: by introducing informatization software, Nanyang can transform from a loose management approach to a more refined management model (such as ERP, MES, WMES, equipment management system, project management system, and personnel management system etc)

Lean Production: through continuous upgrading of production line automation; the introduction and application of warehouse WMES, and the pull-style production based on minimum inventory and maximum possible production flow.

Precise data: Through the application of information software, the management of the entire process of Inventory entry and exit quantities in Nanyang, as well as the management of quality inspection data, all achieve automatic extraction of data.

Precise Traceability: through the QR codes on the surface of the spindle; the QR codes on the BMC injection molding surface, and the QR code at the end of the rotor shaft of the entire machine. These three elements are interrelated to achieve quality traceability throughout the entire process, entire production line, and entire life cycle of the motor.

Huzhou Nanyang Electric-Motor Co., Ltd.

Committed to the development and production of precision drive systems and providing customers with intelligent drive solutions and customized services for the production and assembly of precision parts.