R&D center

In Nanyang, every year, we directly inject 5.6% of our revenue into a 1,200㎡ science and technology innovation center backed by five joint laboratories of Harbin Institute of Technology, Southeast University and others, with over 76 undergraduate and postgraduate talents flowing in a "revolving door" style, and expert advisory teams stationed in Japan and South Korea, it ensures that every current commutation in Nanyang leads the industry by half a step. 2030 goals: for every 100 washing machines in the world there are 30% of "Nanyang hearts".

Nanyang Electric regards the "external brain" as the "internal brain". There are 4 resident experts in Japan and South Korea, 6 university professors who have signed contracts based on research projects, and an international Fellow will conduct online reviews. Electromagnetic, thermal management, low-dysprosium magnetic steel, AI simulation... Each difficult problem is stamped by a designated person. The achievements are patented. Last year, the consultant participated in 20% of the new products, and the unit cost was further reduced by 5%. Global professional brain, signed with a Nanyang work license.

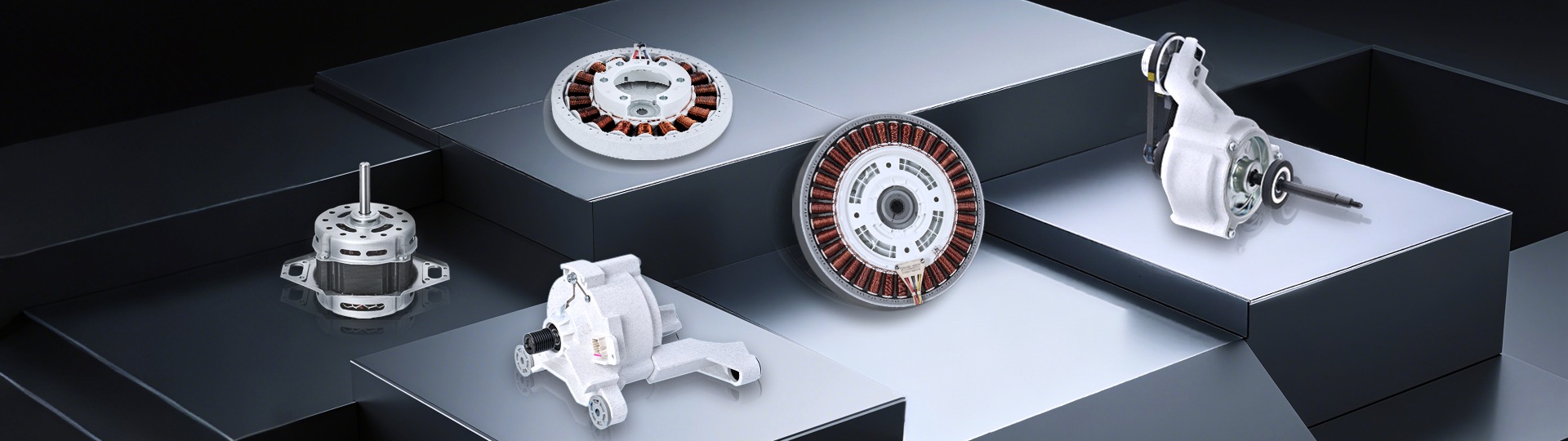

BLDC Rotor spacer tooth breaking technology

Enhance efficiency: By reducing eddy current losses and improving magnetic flux utilization, the overall efficiency of the motor (especially at the rated point and high-speed range) is enhanced.

Increase power density: Under the same volume and weight, the motor can output greater power and torque.

Improve high-speed performance: The increase in iron loss at high speed is effectively suppressed, resulting in better high-speed performance and stronger overload capacity of the motor.

Optimize back EMF waveform: Through precise design of the shape and position of the "skipped teeth", the distribution of the air-gap magnetic field can be optimized, making the back EMF waveform closer to the ideal sine wave or square wave, thereby reducing torque ripple and operating noise.

Dual rotor DD motor design

The technology of sharing the same stator core for two sets of windings, both internal and external, is achieved through the following methods:

Design a thick and isolated yoke in the middle of the stator core to provide independent low-magnetic-resistance paths for the internal and external magnetic circuits.

Utilize model-based feedforward compensation or decoupling control algorithms to calculate and counteract the magnetic field interference caused by the other set of windings in real time.

Overall plastic molding technology for BLDC motor

Reduce the vibration and noise of the product

Excellent sealing performance and environmental adaptability

High degree of integration and lightweight design

Enhance electrical safety and insulation reliability

Improve thermal management

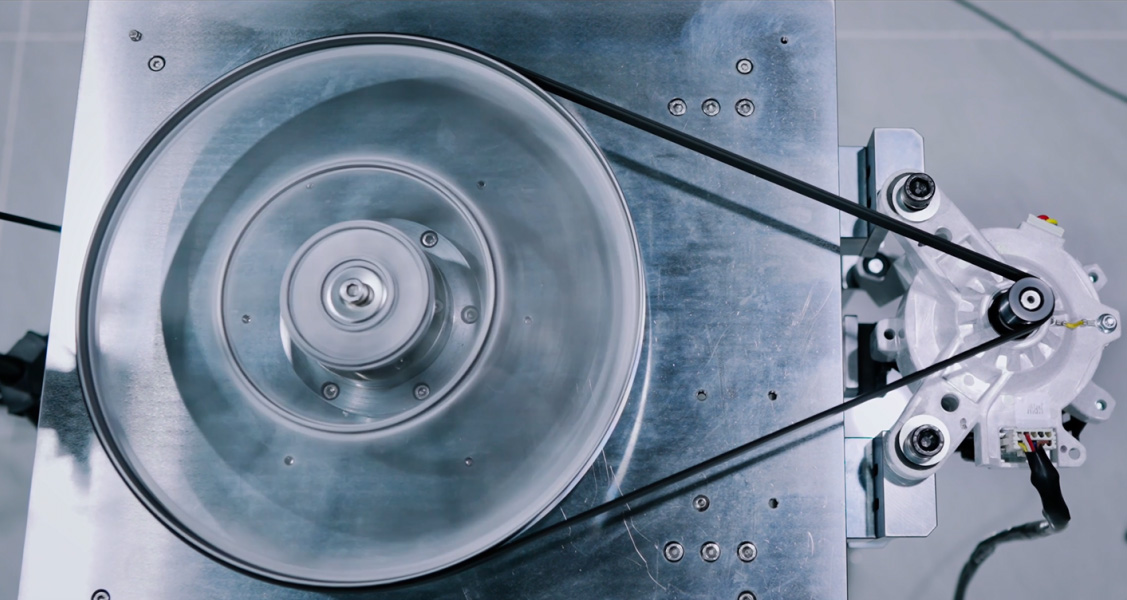

Umini-Pin Flat Wire

Nanyang Motor has built the industry's first Umini-Pin flat wire stator production line, with an annual design capacity of 240,000 units. It can seamlessly switch between Hair-pin, Umini-pin, and X-Pin processes. The forming station is equipped with an automatic tool replacement system, allowing for the one-click switch to X-Pin type wires; the entire line performs automatic wire insertion, and the Umini-pin online cutting and welding integrated fixture compresses the straight section of the welding end to ≤5 mm. This effectively reduces costs and makes the product more lightweight. All key processes adopt full laser technology, and multiple anti-defect, error-proof, and online cleaning mechanisms are implanted to achieve "unmanned" high-cleanliness production of the stator

Standard

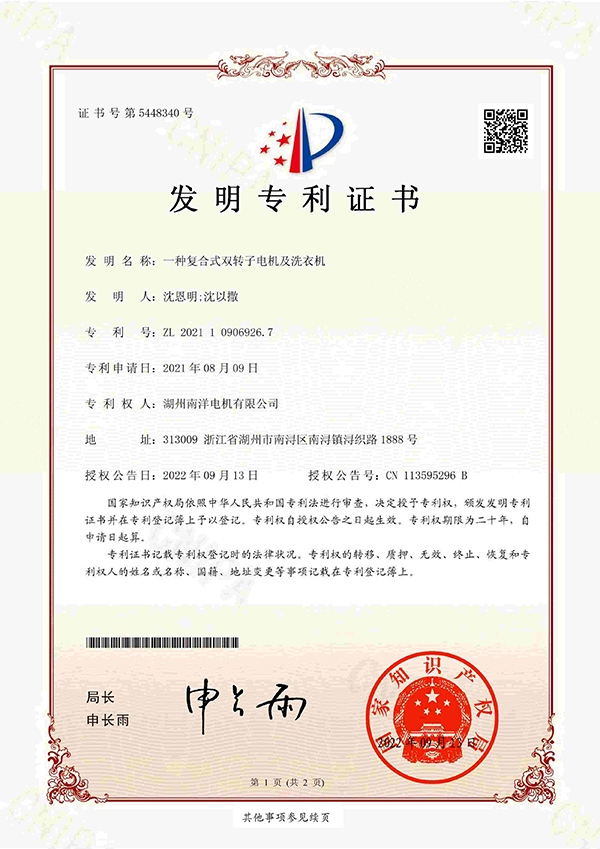

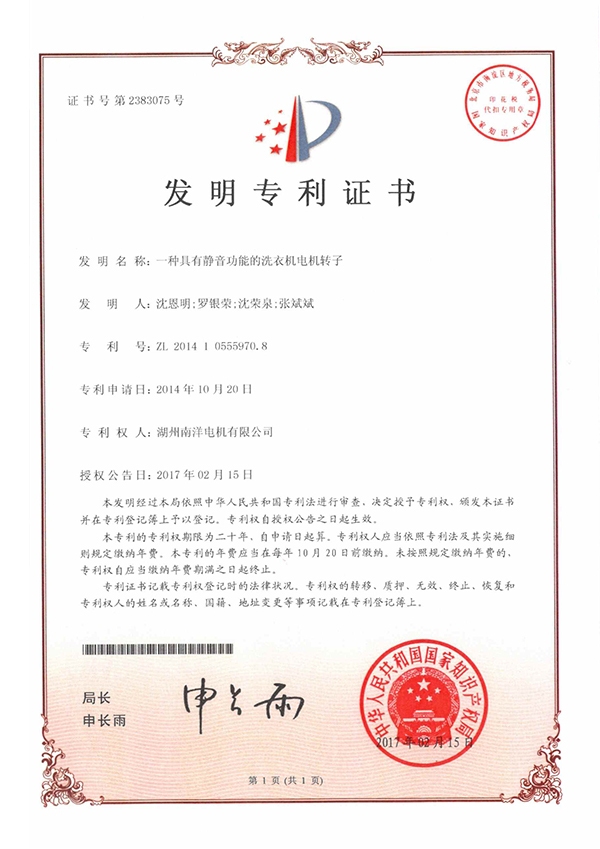

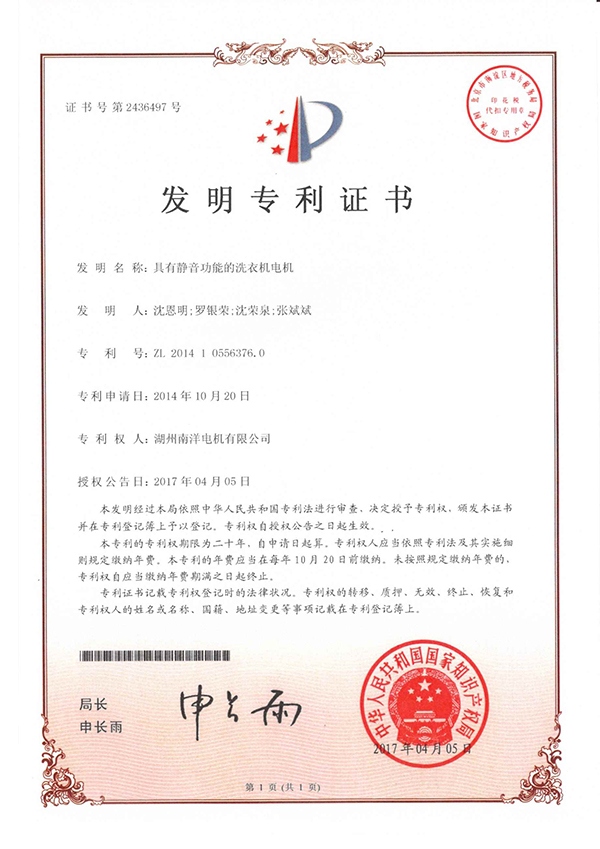

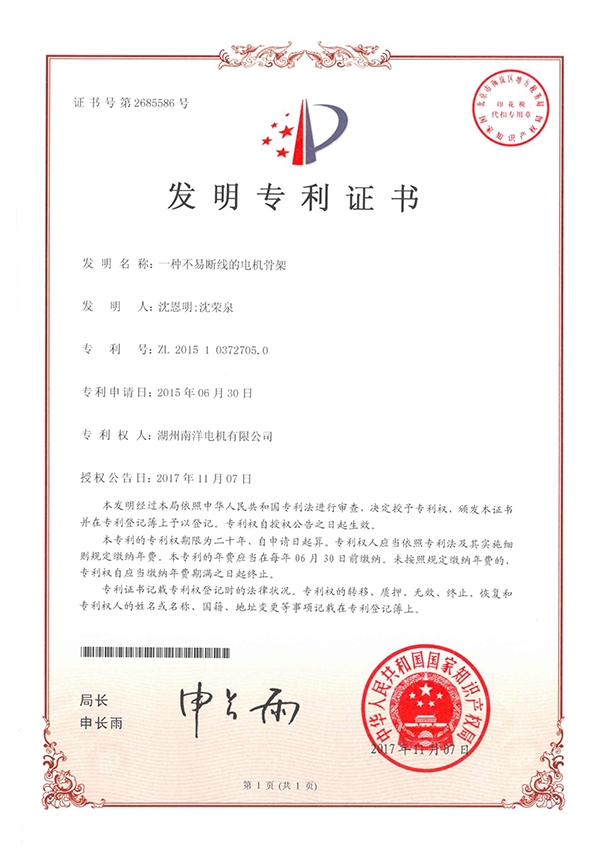

Patent Certificate

Huzhou Nanyang Electric-Motor Co., Ltd.

Committed to the development and production of precision drive systems and providing customers with intelligent drive solutions and customized services for the production and assembly of precision parts.