Multi-physical Field Coupled Motor Limitation Design Platform

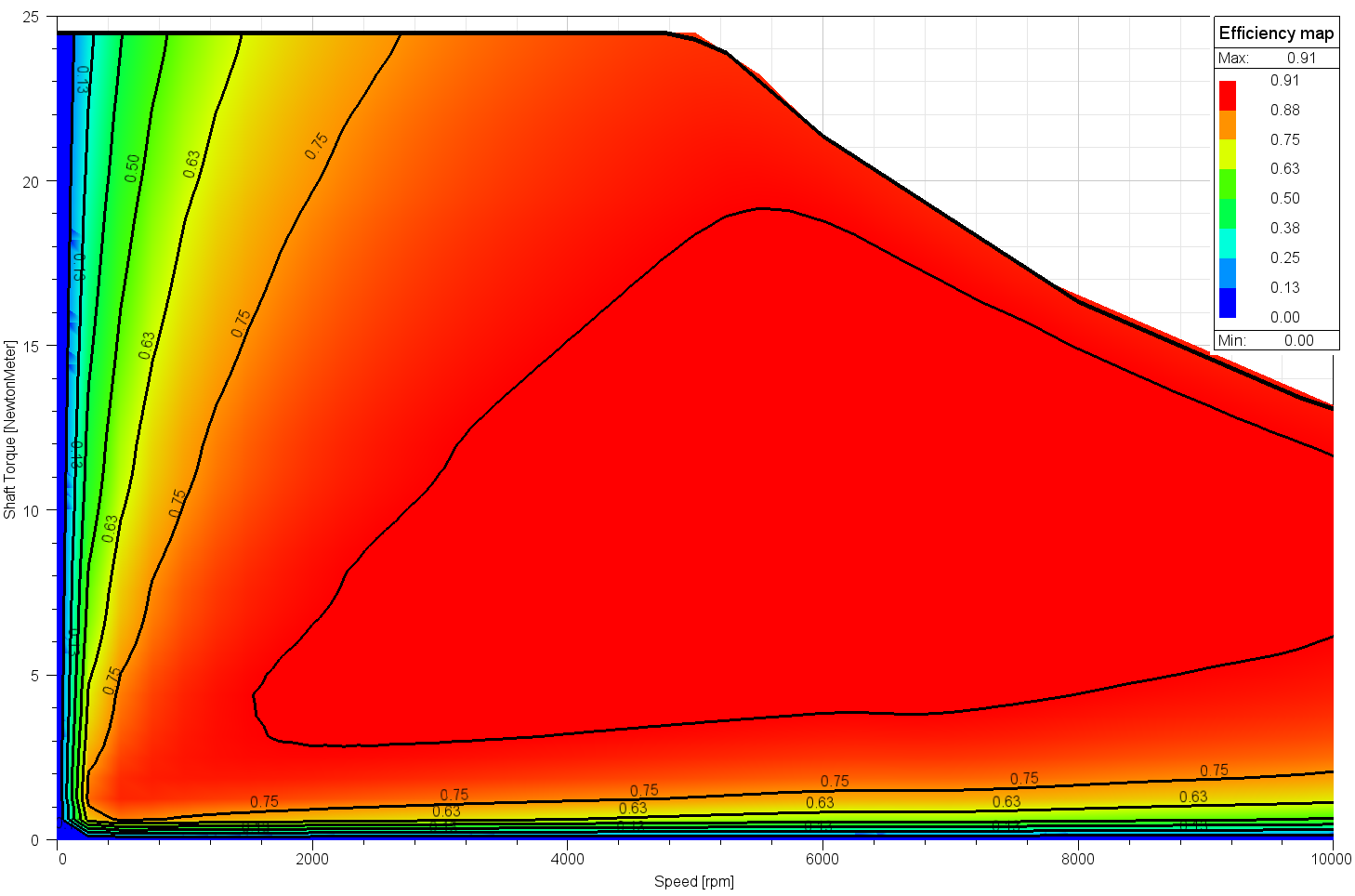

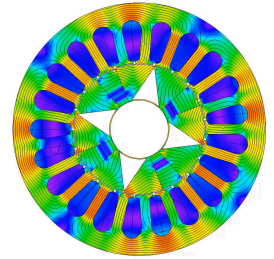

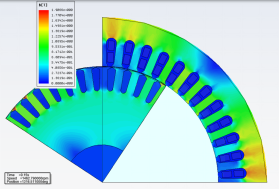

Under the joint guarantee of motor electromagnetic design and motor control strategy, a “four-dimensional multi-physics field coupling design platform” for “electromagnetic-thermal flow-vibration noise-mechanical strength” is constructed to achieve synchronous optimization and extreme exploration of electromagnetic schemes, control algorithms, cooling topology, structural stiffness, NVH (noise-vibration-rustiness) performance; through the bidirectional coupling model of electromagnetic-heat-force-sound and the joint simulation closed-loop of hardware-in-the-loop (HIL) and power-in-the-loop (PIL), the global scanning and Pareto frontier search of multi-objective extreme boundaries such as high power density, high rotational speed, high torque pulsation suppression, low vibration noise, and high reliability are carried out; ultimately, the optimal solution of the motor system level that balances extreme performance, cost, manufacturability and life cycle reliability is delivered.

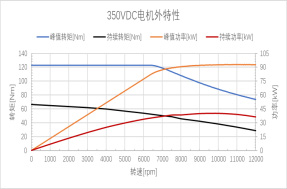

Counter-electromotive force

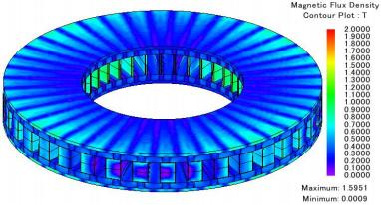

3D magnetic field cloud map

External characteristic curve

No-load counter electromotive force

Cloud map

Variable flux cloud diagram

Magnetic field line cloud map

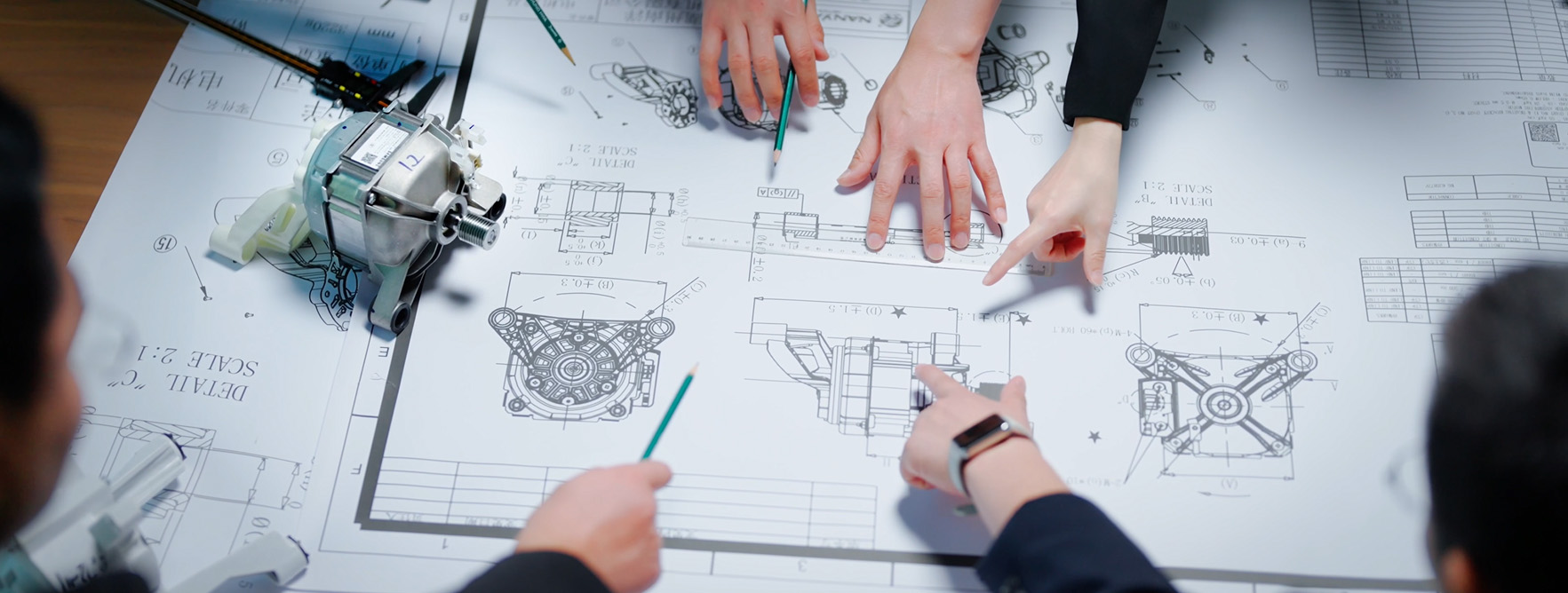

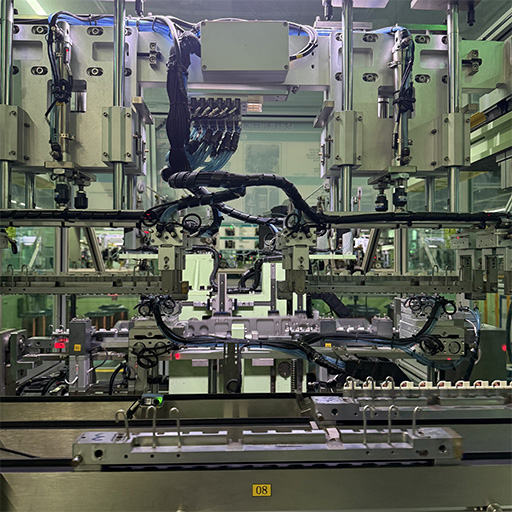

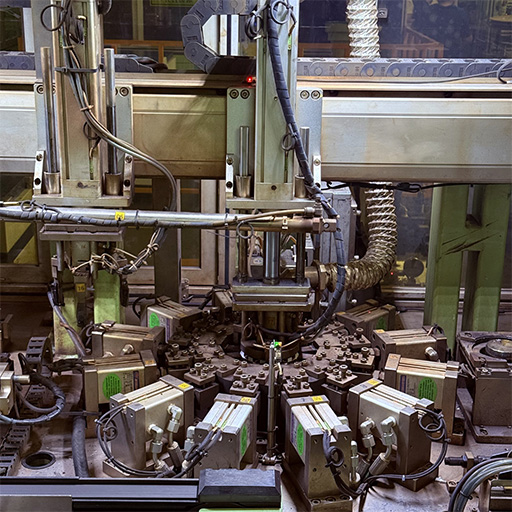

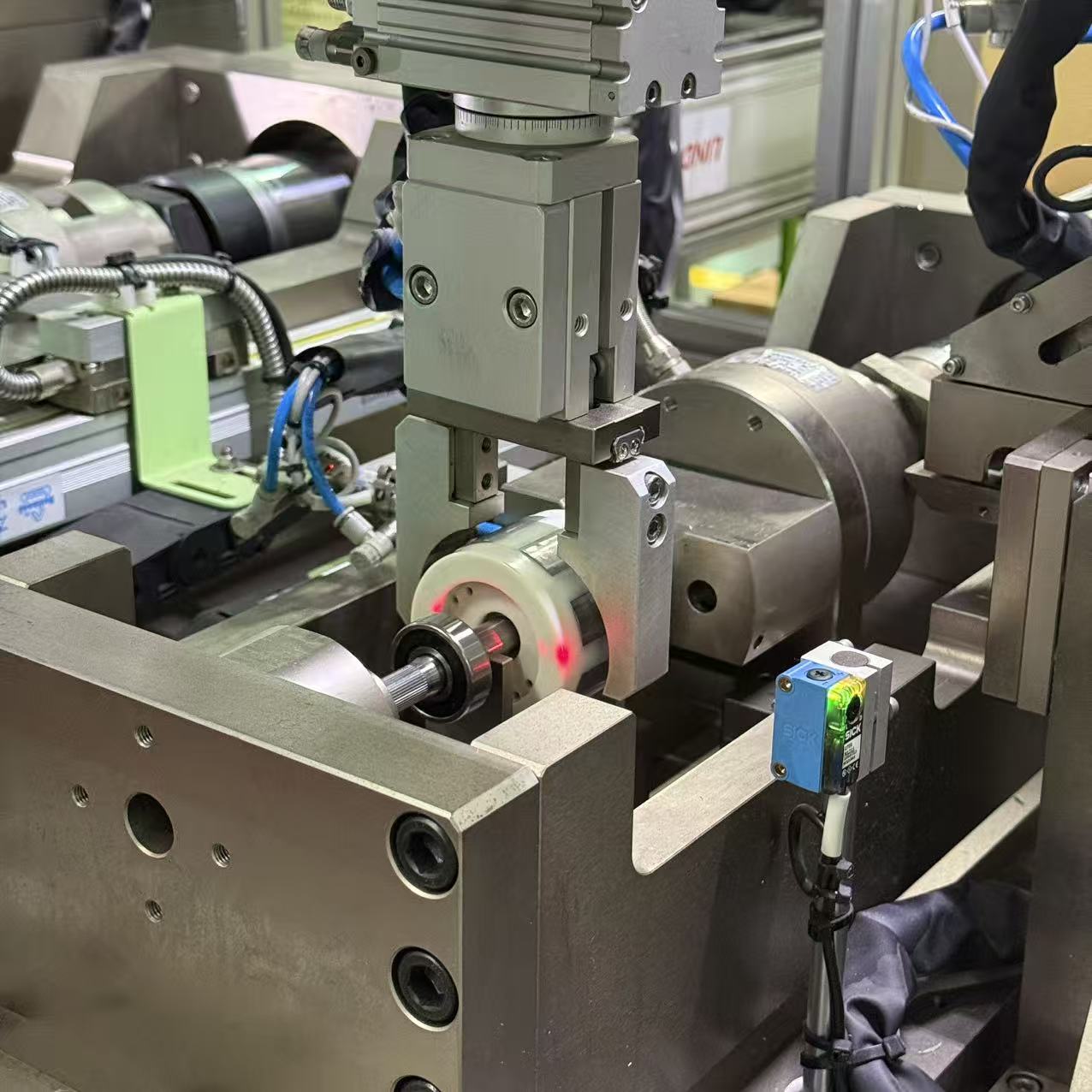

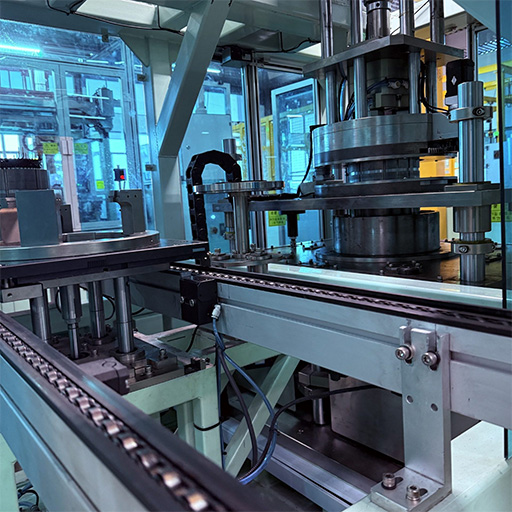

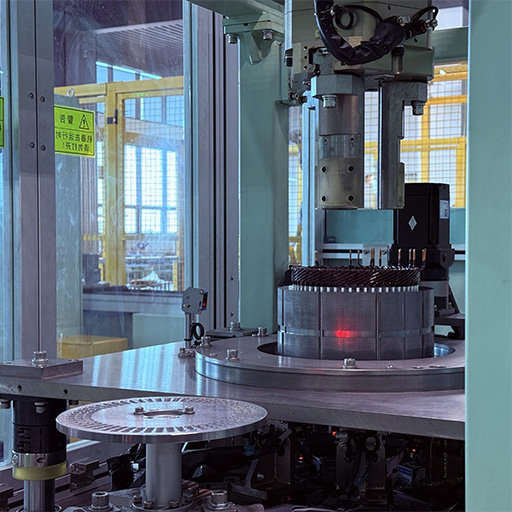

Tooling Design

Based on a deep understanding of the electromagnetic, structural and process characteristics of the motor, we provide an end-to-end service of “product requirements → process decomposition → tool customization → production line integration”: from the stacking of stator and rotor, automatic winding, embedded wire expansion, vacuum impregnation, to final assembly bonding and NVH testing, each process can be customized with high rigidity, quick-changeable, and data-traceable intelligent manufacturing tools, enabling multi-variety and small-batch flexible co-line production. This helps customers lock in the optimal solution for three key indicators: reducing cycle time, improving yield rate and lowering maintenance costs at one time.

Rotor dynamic balancing

Stator winding

Welding

Entry axis and pulley

Box build

Wire forming die

Press into the mold

Turning-head mold

Software Design

Committed to motor control module development

Fluent

Engineering innovation through advanced CFD simulation

Mechnical

Powering structural innovation through high-fidelity simulation

Electronics Desktop

Driving electronic system innovation through integrated EM and circuit simulation

Huzhou Nanyang Electric-Motor Co., Ltd.

Committed to the development and production of precision drive systems and providing customers with intelligent drive solutions and customized services for the production and assembly of precision parts.